WELCOME to TROSKA

Digital Manufacturing for Early Prototyping to Final Production

We are the fastest and most comprehensive manufacturer in the world. Get an online quote for parts within days or talk with a production expert for solutions across your entire product life cycle.

Our Manufacturing Services

Injection Molding

Get affordable, high-quality molded parts and bridge tooling within days. With our free moldability consultation, the design and molding process is rapidly accelerated to save you time and money.

- Low-volume molding up to 100,000+ parts with volume pricing available—no MOQ required.

- 100+ plastic, elastomeric, and silicone rubber materials.

- Automated CMM for fast, in-house quality documentation.

- 24-hour quotation system + DFM analysis support, the first batch of samples can be delivered in 72 hours at the earliest.

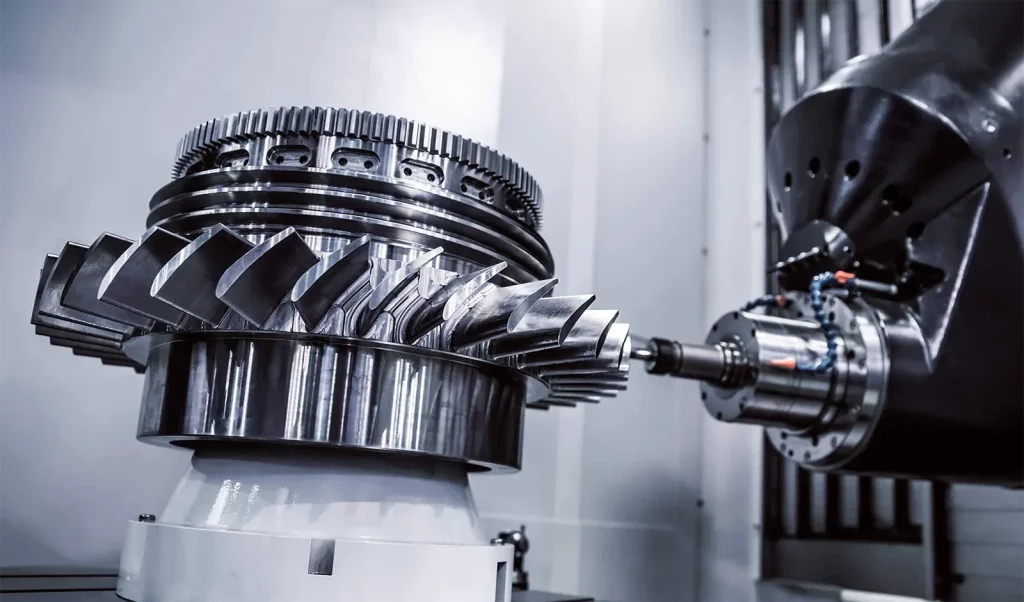

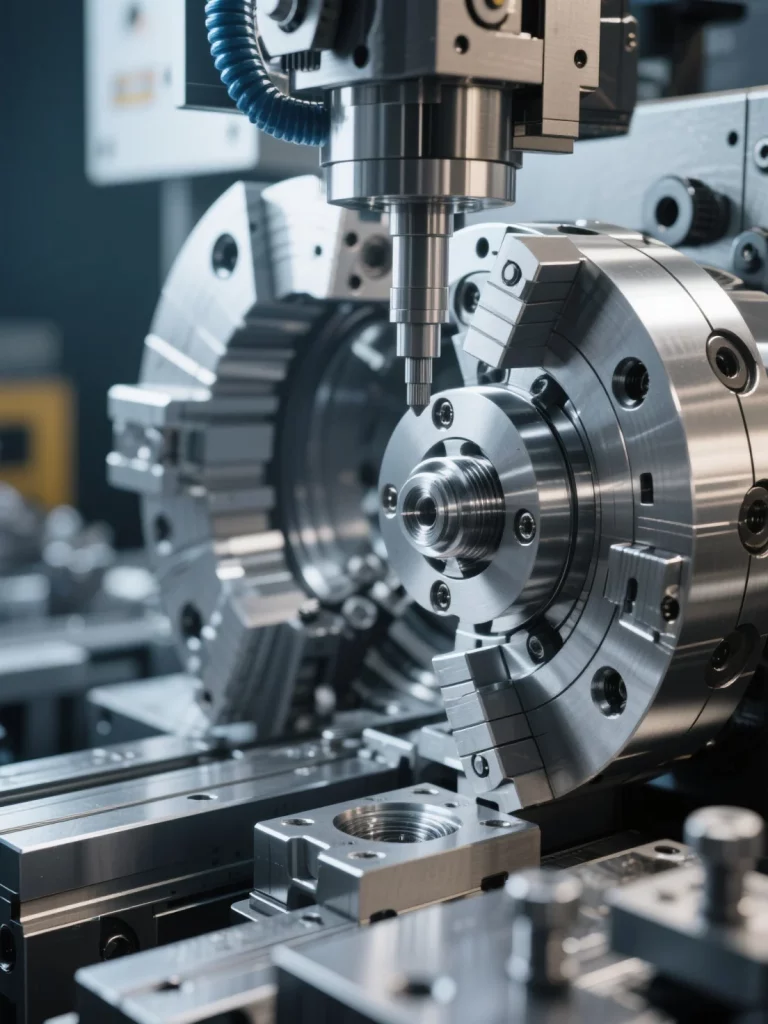

CNC Machining

Leverage the same speed, precision, and reliability in machining that you’re accustomed to at Protolabs but unlock advanced machining capabilities like tighter tolerances and volume pricing through.

- Machined parts in as fast as 1 day with optional plating and anodizing in as fast as 4 days.

- Cost-efficient machined parts at higher volumes.

- Tolerances down to ±0.001 in. (0.020mm) through our digital network.

- Provide 20+ processes including hard anodizing (MIL-A-8625), chemical nickel plating (AMS 2404), RoHS compliant electroplating, etc.

3D Printing

Want quality parts and additive expertise at a single 3D printing source? Choose from seven different additive manufacturing technologies for cost-effective prototyping and highly precise.

- Additive technologies include metal 3D printing, SLA, SLS, FDM, and more.

- 30 plastic and metal materials in a range of finishes.

- 25 years of additive manufacturing expertise.

- Supports large-scale additive production of 1,000+ pieces.

Sheet Metal Fabrication

From easy quoting to quick-turn production and finishing options, get up to 500 quality sheet metal parts in your hands in days from a single supplier.

- Instant quotes with interactive manufacturability feedback.

- Six sheet metal materials including aluminum, stainless steel, steel, brass, and copper.

- Finishing options from welding and hardware insertion to powder coating and silk screening.

- High-precision bending, minimum bending radius 0.5T (plate thickness), tolerance ±0.1mm.

Manufacturing Like a Pro

We're your single resource from prototyping to production. Partner with us to accelerate product development and get to market faster than ever before. When you're ready for production, get complete program management with a team of manufacturing experts who will help optimize your project around cost, quantity, and quality.

We have accumulated more than 20 years of extensive experience in the CNC machining and manufacturing industry.

Because of advanced technology, we already have more than 80 stable partners around the world.

Why Choose Us

- As a ISO-certified CNC machining manufacturer, we combine advanced 5-axis machining centers with rigorous quality control to deliver complex parts with ±0.01mm accuracy.

- With real-time production updates and dedicated project management, you get transparent communication at every stage – because your success is how we measure ours."

Technical Capabilities

30+ CNC machines including 5-axis and Swiss lathes deliver ±0.002mm precision. Smart MES enables full digital production with 150K monthly capacity. Specialized in titanium alloys with advanced cooling systems.

Industry Solutions

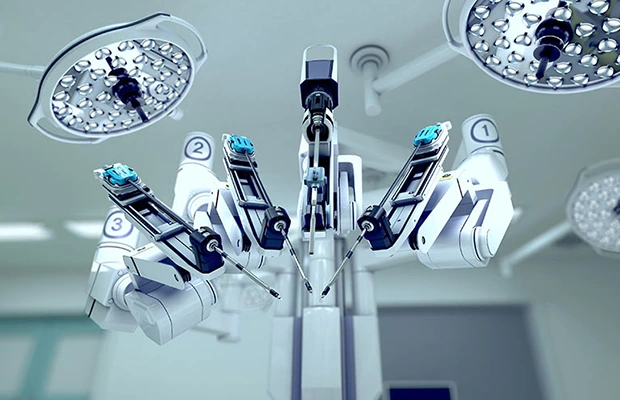

Medical cleanroom implants, AS910D aerospace components, and EV automotive solutions. Prototyping to mass production with material expertise in titanium/PEEK.

Quality Certifications

ISO 13485 & IATF 16949 certified with CMM inspection. SPC-controlled processes achieve 99.98% quality rate. Full material traceability guaranteed.

Main Application Industries

Specializing in aerospace, medical devices, and automotive components, we deliver tailored solutions:

Aerospace

ITAR-compliant machining for airframe structures and engine parts (AMS/AS9100 compliant).

90%

CNC penetration rate of aircraft engines.

Automotive

High-volume production of EV motor housings and drivetrain components (IATF 16949 system).

75%

Automobile turbocharger CNC penetration rate.

Medical

Implant-grade titanium/PEEK machining with cleanroom protocols (ISO 13485 certified).

60%

CNC penetration rate of medical endoscope parts.

Your Industry isn't Listed?

CNC Machining Solutions Verified by 300+ Industry Customers.

Latest News from Blogs

Follow us to get more CNC industry information, you can also directly consult the technical team to solve current production problems.

May 9, 2025

May 9, 2025

Professionally provide one-stop solutions for CNC turning and milling composite processing and OEM manufacturing.

Service

- Injection Molding

- CNC Machining

- 3D Printing

- Sheet Metal Fabrication

Solutions

- Aerospace

- Medical Device

- Automotive Industry

Contact Info

- Huashan Middle Road, Xinbei District, Changzhou, China.

- service@theme-solutions.com

- +86 18023456789

- Privacy Policy

- Terms Conditions